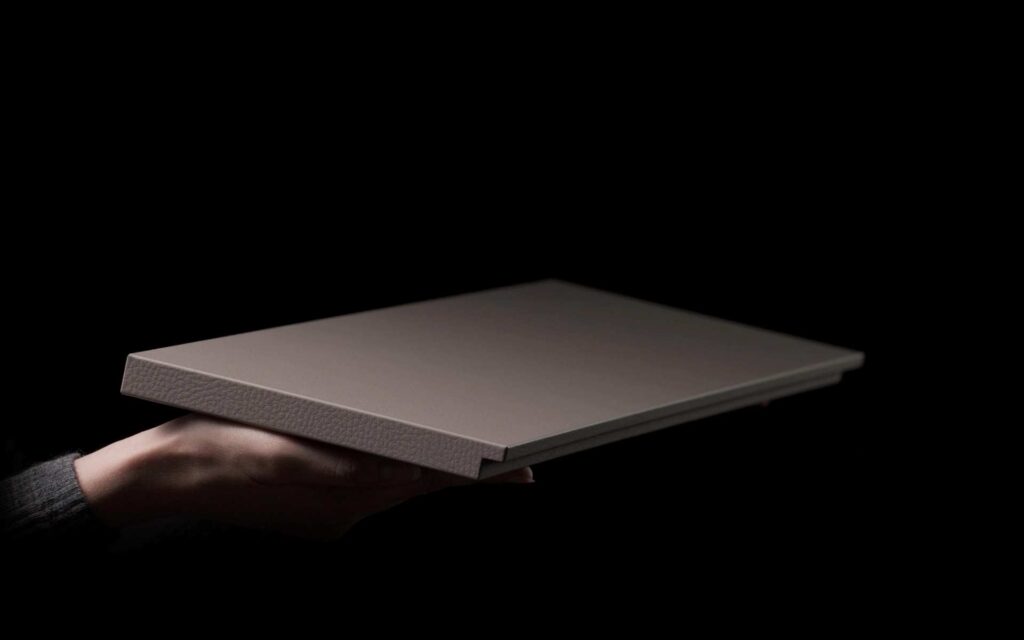

Founded in 1956, Pianca sets a standard of excellence in the furniture industry. It specialises in the creation of systems and furnishing accessories for both sleeping areas and living areas. Pianca has an approach to design focused on the customisation of products and spaces, aimed at meeting the style requirements of flexible, mobile and change-oriented living.

To preserve the manufacturer’s authenticity and continue to offer customisation options, production improvements were needed. Pianca therefore successfully partnered with Cefla Finishing to maintain its signature level of customisation while at the same time increasing productivity – which had been negatively affected by frequent colour changes.

The new Cefla Finishing coating system replaced three obsolete lines with a single high-performance line, able to significantly reduce machine downtime and automate processes previously performed manually.

In an industry where uniqueness is an increasingly valuable asset, the ability to offer an endless range of colours and finishes, even for single pieces, is hugely appreciated. How is it possible to develop an efficient industrialised production process when large-scale production is not feasible?

Cefla technologies combine productivity and customisation: optimising the colour changeover process was key to making a huge impact on Pianca’s productivity. One such technologies is Timeskip, the patented device allowing the line robot to continue coating with one arm, while the other arm can carry out colour changeover or maintenance operations.

Thanks to the newly introduced technology, the new Pianca plant has revolutionised the company’s finishing process, optimising finishing in a single production cycle, completed by a vertical oven for drying the material and optimised by line software to streamline the complex management of frequent customisation requirements.

From a sustainability point of view, the new coating system allows waste to be minimised, both in terms of downtime and in terms of product loss.

>>> READ THE COMPLETE CASE STUDY ON CEFLA FINISHING WEBSITE!