What is innovation for us?

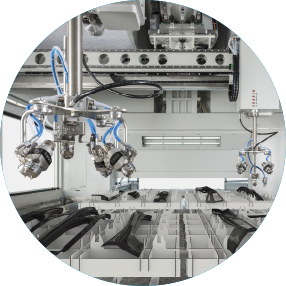

The Finishing BU has a long history of designing and building tailor-made ‘turnkey’ finishing lines for the wood market. Today, it also leads the way in the glass, plastic, fibre cement, composite materials and metal sectors.

With over 60 years’ experience, the Finishing BU helps bring innovation to the world of finishing.

This expertise – which is shared throughout the organisation – is unique, making us the most reliable partner on the market, whatever your finishing needs.

To achieve all this and deliver innovation demands a new approach to product marketing that explores the user’s latent needs and aims to structurally analyse what customers have yet to realise they need.

All this yields a competitive advantage in defining real needs. In an industrial Business to Business sector like our own, that process requires careful nurturing.

The real innovation is simplification, as it means doing the same thing in a way that’s more straightforward and uses fewer elements.

This reduces complexity and offers up new possibilities.

The Finishing BU has adopted various strategies to simplify operations, such as rationalising corporate organisation and product codes.

Interview with Piero Pracchi

Finishing Business Unit Director

What innovation is the finishing business unit carrying forward most successfully?

“The main innovation consists of simplifying the processes and the product portfolio. This task focuses on getting people involved in implementing structured improvements to the business.

Additionally, problems need to be approached by breaking them down into small ‘opportunities’. For example, to address the raw material procurement crisis, we’ve separated the roles of the person buying and the person ordering. This allows us to obtain better terms of purchase by placing a negotiation specialist in the role of the buyer, consequently lowering costs, and putting a separate professional in charge of production line procurement. When taken as a whole, these small changes lead to tangible innovation and more efficient processes.”

How does the market benefit and which innovation can be defined as “trending”?

“We’re also committed to increasing processing speed and product quality. This is done by identifying bottlenecks in our customers’ production process and introducing integrated technologies to reduce colour changeover times and optimise coating usage.

“We’re also committed to increasing processing speed and product quality. This is done by identifying bottlenecks in our customers’ production process and introducing integrated technologies to reduce colour changeover times and optimise coating usage.

We also install sensors on machines to reduce the waste associated with coating overspray.

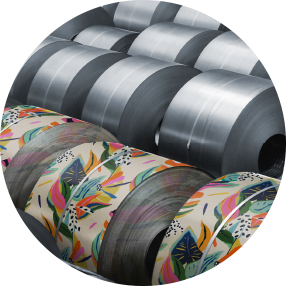

Our innovation provides the market with direct benefits such as optimisation of industrial processes and empowering customers to launch new products. For example, our digital printing solutions let steel manufacturers perform high-resolution, high-speed printing on coils, opening up new design and application opportunities.

This innovation has established a market trend, providing unexplored possibilities and opening up new markets.

We’ve also introduced a concept that boosts production efficiency, a solution that provides a well-organised process that delivers synergy and productivity to end users.”

Is sustainability innovation?

“We’re constantly committed to sustainability. IoT sensors that can remotely control machines and read processing cycles allow us to detect inefficiencies and offer economic improvement services.

This ‘integrated communication’ of inefficiencies allows sustainability and efficiency-enhancing processes to be put in place as the machines work.

Our approach to achieving sustainable innovation in industrial finishing is decidedly data-driven.

Harvested data allows us to offer subscription services and return added value to customers.

This stimulates further improvements and creates an unbroken chain reaction of innovation.”

Interview with Lorenzo Melloni e Gianpietro Galeotti

Marketing Manager and New Product Development Manager BU Finishing

In what way have customers been made the focus of IOT innovation design and digital printing on "unconventional" surfaces?

“Our innovative approach to IoT development and design means that the customer is, today, not just the focus of the process but an active participant in it. Our guiding principle is customer-focused simplification.

“Our innovative approach to IoT development and design means that the customer is, today, not just the focus of the process but an active participant in it. Our guiding principle is customer-focused simplification.

By collating and rationalising daily requests we’re able to map customer’s needs and foster design solutions that respond to specific needs.

We provide the Finishing sector not just with products but finishing processes. Thanks to its multidimensional approach, the company is able to meet customers’ vastly differing needs (global market) with a broad product portfolio (from entry-level to large-scale integrated systems) across numerous industries (wood, plastic, metal, aggregates, glass).”

“In some industries (e.g. wood), we’re recognised as technological first movers. In others we are, at present, explorers. Yet even here, for example in the coating industry, we enjoy a solid reputation for reliability.

In a context of multidimensional complexity, we’re on a path – together with our customers – that leads to the development of products, processes and solutions with one shared goal: to create value and give each customer a competitive advantage.

In recent years, company development has shifted its focus from the Product to the Market (i.e. customer). As trailblazers, we focus on the Process, adopting a strategy that involves customers and suppliers alike.”

How much has technology, in the entire approach described, influenced the innovation process?

“Thanks to our corporate set-up and research facility, we’re able to put together a ‘puzzle’ of micro-processes that provide customers with immediate, tangible solutions. This is possible because close teamwork with coating manufacturers and customers sparks true ‘creative’ innovation.

Cefla Finishing collaborates with research bodies and universities to promote open innovation. For example, it works with DEIX, a spin-off of the Polytechnic University of Rome and Milan, which focuses on digital printing quality management. Furthermore, our partnerships with universities and research bodies aim to develop new control systems and integrate sensors/data harvesting devices on spraying and drying processes.

We’ve also launched an internal project called ‘Beyond 2025’. This seeks to build solutions that leverage AI to help us redefine our business model and address new global challenges such as the skilled labour shortage and the transfer of technical skills to new generations.”

Interview with Raffaele Caliò

Service Manager BU Finishing

Can you tell us about the innovative after-sales service?

“We initially launched an augmented reality service, using supports such as HoloLens glasses to conduct remote assistance with a view to solving problems that occur in the field. This pilot project was short-lived as it was overtaken by the development of everyday devices like smartphones and tablets; consequently, the service is now provided quickly and easily via video call apps.

Another key development was the creation of cMaster, a centralised service platform that uses the cloud to gather machine data.

This easy-to-install solution has made Cefla more agile and reliable. The platform lets customers monitor their machines in real time and view statistical data, warnings and maintenance info.

This system has improved Cefla’s overall after-sales service range.

The introduction of advanced maintenance programmes lets us provide closer customer support and improve machine efficiency. Before these programmes, data was interpreted subjectively and lacked context: that data is now more solid and continuously updated. This enables in-depth log analysis to improve production and optimise processes.

Technology has played a pivotal role in Cefla’s innovation process. Cloud-based solutions, broadband and simplified access to remote assistance have all streamlined the development of cutting-edge maintenance processes. What’s more, new AI technologies have ramped up innovation in after-sales service. For example, Cefla’s cMaster and Control Room use AI to accrete and analyse customer data, enabling real-time monitoring and identification of potential problems. AI is also used to generate maintenance-related notifications and warnings: this raises line efficiency and makes service more proactive.

Cefla is also exploring the potential of purchasing consumables via cMaster. Again, this would simplify and optimise the process. In the future, we expect to develop a spare parts website with a smart interface. We’re also working to create direct problem reporting systems to ensure more efficient, pre-emptive assistance activation.”